What is a Cantilever Rack System?

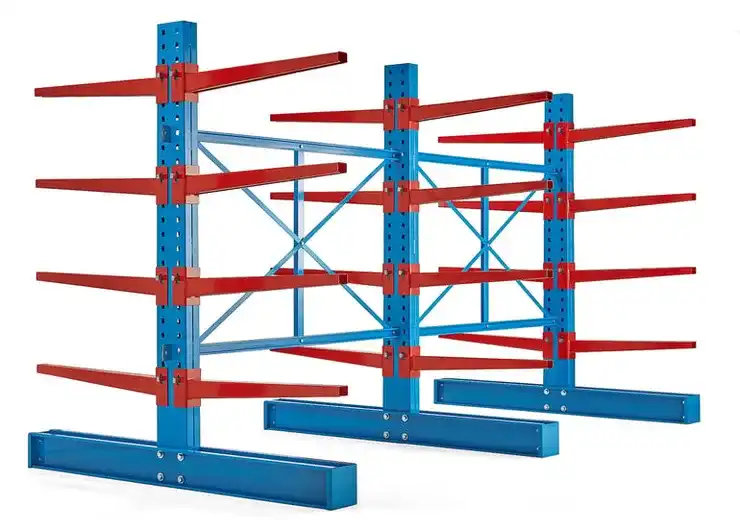

A cantilever rack system is composed of four key elements: uprights (also called towers), arms, bases, and braces. The uprights serve as the primary structural support, while the bases anchor the uprights securely at the bottom. Extending from the uprights, the arms are designed to hold products, and the braces provide additional stability by connecting the uprights.

Cantilever racking systems are highly adaptable, allowing customization to meet diverse storage requirements. They optimize vertical space usage and provide direct access to each load, eliminating the need to shift other items.

Types of Cantilever racking

Single Sided Cantilever Racks

Single sided cantilever racks have arms on one side and are balanced by a large stackable base .

Double Sided Cantilever Rack

Double sided cantilever racks, are installed in the middle of the floor and accessed from both sides.

Light Duty Cantilever Rack

Light Duty Cantilever Rack is also the lowest priced cantilever racking.

Heavy Duty Cantilever Rack

Heavy Duty Cantilever Racks have capacities that range from 2000-4000 LBS. per arm (based on the arm length).

How does it work Cantilever Warehouse Racks?

Cantilever warehouse racks feature a straightforward design, consisting of vertical columns and horizontal cantilever arms. The weight of stored items is evenly distributed across the arms, which transfer the load to the columns. To ensure structural stability, the system includes sturdy bases and braces.

The adjustable arms allow for customization, accommodating products of varying sizes and shapes. This flexibility makes cantilever racks highly adaptable to evolving warehouse requirements, offering a practical solution for diverse storage needs.

Key Benefits of Heavy-Duty Cantilever Racks

- Sturdy, Simple Structure: Built to handle heavy loads with a durable, straightforward design.

- Versatile Storage: Accommodates various product shapes and sizes, ideal for diverse inventory.

- Direct Access: Allows easy retrieval of items without moving others, enhancing efficiency.

- Adjustable Arms: Customizable to meet changing storage needs.

- Space Optimization: Open design maximizes floor space for higher storage capacity.

- Easy Installation and Maintenance: Quick setup and low upkeep reduce costs and time.

- High Mobility: Facilitates smooth handling and movement of goods, improving workflow.

Components of the Cantilever Racks

Cantilever Uprights

Vertical supports with perforations for adjustable arm placement.

Cantilever Bases

Provide stability and may serve as an additional storage level.

Cantilever Arms

Horizontal supports for loads, adjustable to fit various storage needs.

Cantilever Horizontal Braces

Horizontal and diagonal elements connecting columns for enhanced rigidity and stability.

Cantilever racking system applications

Cantilever racks are freestanding storage solutions designed for efficient organization of long and heavy items, such as pipes, steel bars, lumber, or tubing. Unlike traditional racks, they lack vertical end supports, allowing easy access and flexible storage for oversized materials. Available in various sizes, capacities, and configurations, cantilever racks can be tailored to meet diverse storage requirements, making them a versatile choice for warehouses and industrial settings.

Warehouses with extra-long products

Cantilever racking is ideal for organizing and storing long, heavy items like pipes, profiles, and moldings

Storage for Non-Palletizable Inventory

Cantilever racking is ideal for organizing and storing long, heavy items like pipes, profiles, and moldings

Versatile Storage for Bulky, Non-Uniform Loads

Cantilever racks provide a flexible solution for storing large, irregularly shaped items of varying weights and sizes, ensuring efficient organization and accessibility.

FAQs

What Does Cantilever Mean?

The term “cantilever” refers to a structural design where a beam or arm is anchored at one end to a vertical support, with the other end extending freely. In racking systems, this design allows cantilever racks to support heavy or lengthy items without front-facing obstructions, offering flexibility and accessibility for various load types.

What Types of Unit Loads Can You Store on Cantilever Racking?

Cantilever racking is highly versatile and excels at storing non-palletizable or oversized items, including:

- Long items: Pipes, tubes, lumber, and metal profiles.

- Flat materials: Wooden boards, metal sheets, and panels.

- Bulky goods: Furniture, carpets, or rolled materials.

- Irregularly shaped loads: Items with varying sizes or weights, such as construction materials or industrial components.

The open design accommodates diverse load dimensions, making it a go-to solution for industries like manufacturing, construction, and retail.

Is It Possible to Store Palletized Loads on Cantilever Racks?

While cantilever racks are primarily designed for non-palletized loads, they can be adapted to store palletized loads in specific scenarios. By adding decking or custom supports to the cantilever arms, pallets can be accommodated.

However, traditional pallet racking is typically more suitable for standard palletized goods due to its optimized design for uniform loads.