Interested in finding out more about Radio Shuttle Racking System or ACL Radio Shuttle for your warehouse? Request more information now.

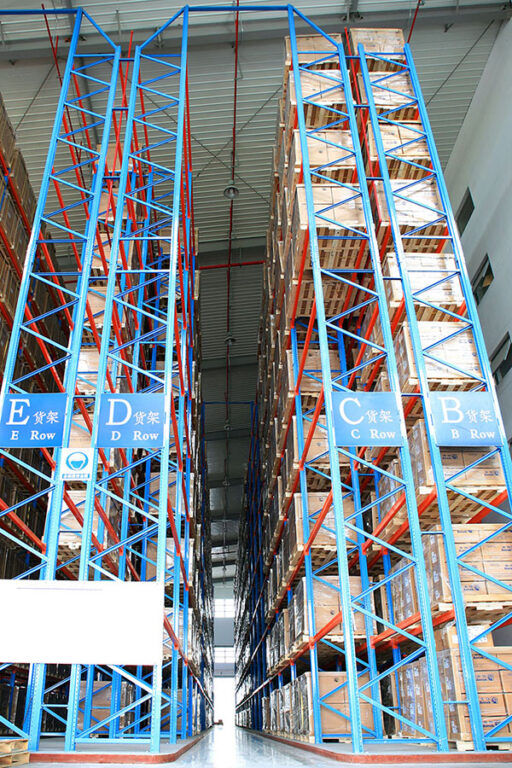

Radio shuttle racking system is a semi-automated high-density storage solution for storing goods, which uses an automatic device to move in the channel back and forth for transportation, with forklift picks up at the end. This radio shuttle solution considerably reduces operating times and enables SKUs to be grouped by channels rather than by entire lanes.

This Radio Shuttle is a self-powered device that runs on rails in the storage lanes for the loading and unloading of pallets. The automated system guarantees the highest possible storage density. Radio Shuttle is especially effective for distribution or logistics centers, where you may need quick and efficient supply and distribution.

This pallet storage and retrieval system allow maximum storage capacity optimization as it reduces the need for aisles between racks. They are often used in warehouses and distribution centers for food and beverages, or in warehouses with special storage conditions. This system allows you to store pallets in varying depths depending on specific needs or seasonal loads. At the same time, each tray can be quickly accessed.

The radio shuttle rack is widely used in food & beverage, cold stores, chemicals, automobiles, logistics centers, and the chemical industry, which will improve work efficiency and save labor costs.

Shuttle racking can change warehouse performance and capacity, especially first-in-last-out (FILO) and first-in-first-out (FIFO) systems.

By designing large, high-density racks with virtually zero aisles, shuttle racking can significantly increase the number of pallet positions on systems such as APR, push-back racking, and drive-in racking.

Interested in finding out more about Radio Shuttle Racking System or ACL Radio Shuttle for your warehouse? Request more information now.

Our Radio Shuttle comes in 8 styles: Economic Type, Standard Type, High-configuration type, Heavy loading type, and Low temp. type, Wifi type, Stacker type, M/S type. The following two tables are their technical parameters.

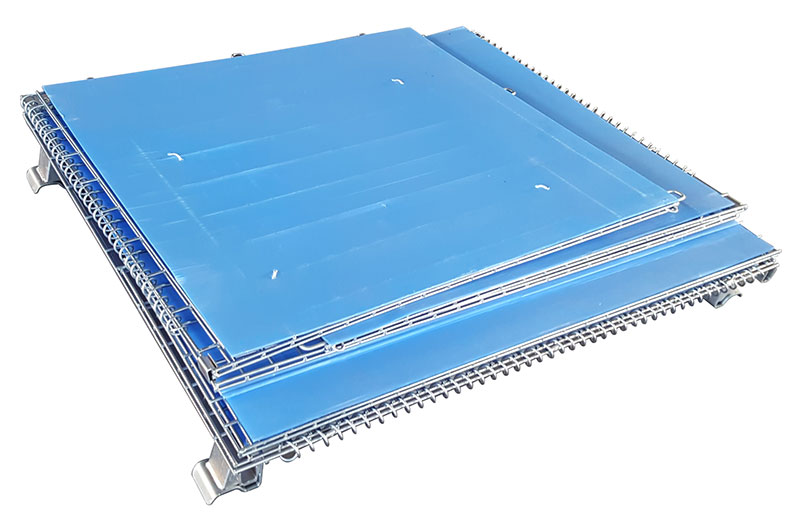

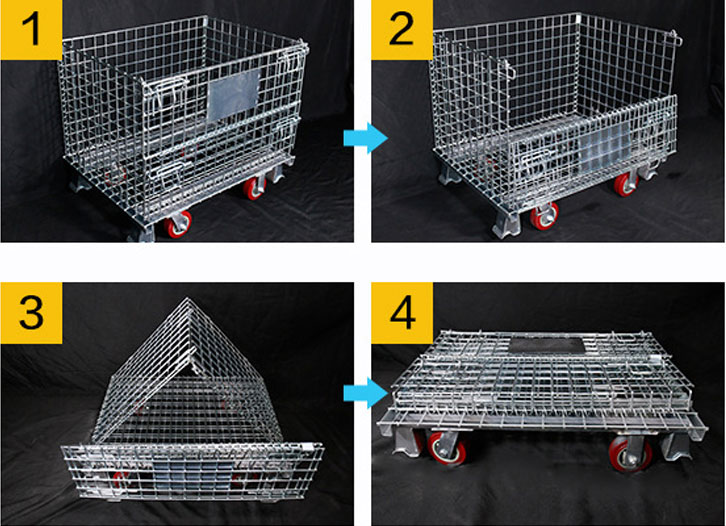

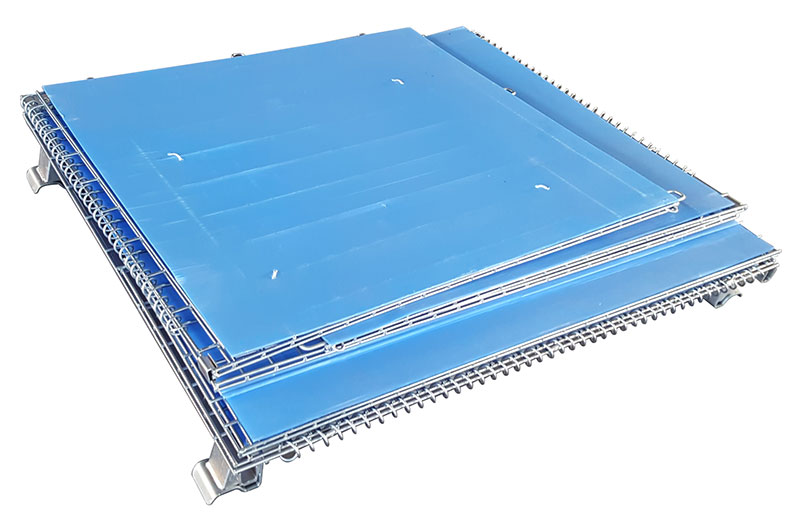

The foldable structure of the collapsible wire container provides convenient storage and fetch. When stacking wire containers, you can open the half-drop door and the back wall at any time for you to store or take out items, eliminating the trouble of digging out the warehouse, and the side wire mesh can bear the weight of stacking. they are welded from high-strength steel wires, which provides them with high loading capacity.

The half-drop gate can provide easy access for storage and fetching goods, and the powder-coated surface ensures corrosion resistance.

Welded by high-strength steel wires and with a galvanized surface, the wire container has a high loading capacity and is anti-rust.

The folding wire container is easy to load, flow, and store, it is produced according to international standards and can be used in conjunction with the container.

Flower Trolley is also called Danish Trolley, Flower Cart, or Greenhouse Trolley.

Flower trolleys are specially designed to support you in transporting flowers and plants. Since the danish trolley is equipped with wheels, it is easy to move. This allows you to quickly and easily restock your store.

These height-adjustable plywood shelves are designed for flower and plant trays of various sizes. Ideal for the optimal protection of your flowers and plants during transport. You can access your Danish stroller anytime, anywhere. This reduces your shipping movements and increases your flexibility. Reduces distribution and shipping costs. reduce carbon dioxide emissions.

Danish trolleys consist of three parts: base, uprights, and height-adjustable plywood shelves. Thanks to the height-adjustable shelves of the danish trolley, all types of flowers and plants can be transported.

The base comes with high-quality 2 x 5" casters for a smooth ride and durability. Each cart fits 2 straight casters and 2 swivel casters. Other casters are customizable and can be made to your specific size or according to our standard size chart Custom cart base. You can add your company name and ID tracking.

The surface treatment uses hot-dip galvanizing, powder coating, or electro-galvanizing, which is wear-resistant and can be used in extreme temperatures.

We supply high-quality various trolleys for warehouses, and flower pot trolleys for greenhouses. Such as plywood trucks, expanded steel floats, shed trucks, Danish trucks, plant trucks, etc., Interested in finding out more about Flower Trolley or Flower Trolley Options for your warehouse? Request more information today.

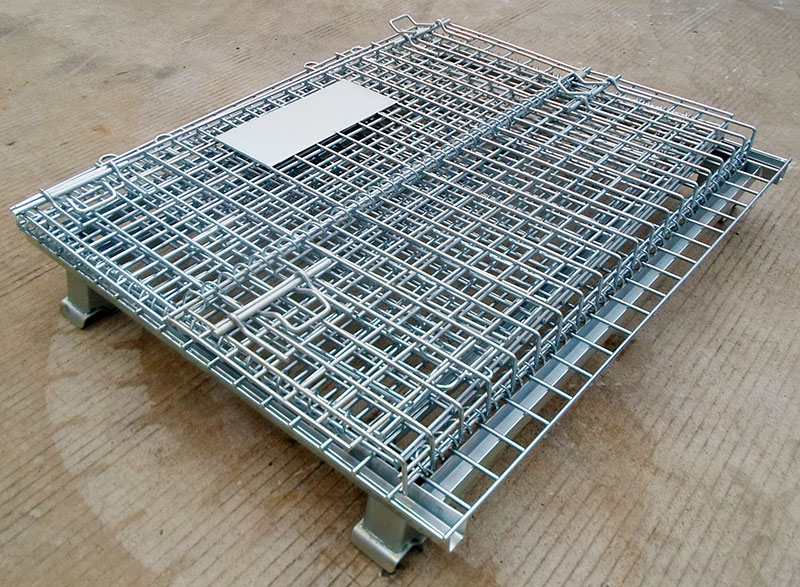

Wire Container is also known as Butterfly Cage, Storage Cage, and Warehouse Cargo Cage. It is a metal cage with a mesh structure for storing goods. It has the characteristics of fixed storage capacity, neat stacking, intuitive storage, and convenient inventory.

Our Wire Container is welded by strong steel wires. Except for the bottom frame, the cage body is a combination of steel wire mesh butt welding. The mesh with mesh and the mesh with the bottom frame are connected by spiral hinges and can be moved. The bottom is reinforced with U-shaped steel beams, which have high strength and strong bearing capacity. Can stackable, three-dimensional storage.

Every part of the wire container has its advantages and they are all combined together to support a stable and rigid structure of the wire container.

Structure of Wire Container

Aceally provides all types of wire containers above. We have a variety of models and sizes available for customers to choose from, OEM & ODM acceptable.

| External dimension (L × W × H) (mm) | Capacity (kg) | Volume (m3) | Wire dia (mm) | Leg height (mm) | Mesh grid (mm) |

|---|---|---|---|---|---|

| 800 × 600 × 650 | 700 | 0.22 | 6 | 100 | 50 × 50 |

| 800 × 600 × 650 | 500 | 0.22 | 6 | 100 | 50 × 100 |

| 1000 × 800 × 850 | 1200 | 0.51 | 6 | 100 | 50 × 50 |

| 1000 × 800 × 850 | 800 | 0.51 | 6 | 100 | 50 × 100 |

| 1200 × 1000 × 900 | 1500 | 0.84 | 6 | 100 | 50 × 50 |

| 1200 × 1000 × 900 | 800 | 0.84 | 6 | 100 | 50 × 100 |

| 800 × 600 × 650 | 800 | 0.22 | 6.4 | 100 | 50 × 50 |

| 800 × 600 × 650 | 600 | 0.22 | 6.4 | 100 | 50 × 100 |

| 1000 × 800 × 850 | 1500 | 0.51 | 6.4 | 100 | 50 × 50 |

| 1000 × 800 × 850 | 1000 | 0.51 | 6.4 | 100 | 50 × 100 |

| 1200 × 1000 × 900 | 2000 | 0.84 | 6.4 | 100 | 50 × 50 |

| 1200 × 1000 × 900 | 1000 | 0.84 | 6.4 | 100 | 50 × 100 |

Every part of the wire container has its advantages and they are all combined together to support a stable and rigid structure of the wire container.

Roll container is also called Logistics Trolley, Grid Trolley, Warehouse Trolley, or Roll Cage Trolley. It is a unitary mobile container with four wheels, capable of carrying different weights. It improves logistics distribution and is famous for its mobility.

Logistics Trolley is the ideal material handling equipment for the transportation, laundry, and logistics industries. It is usually used for supermarket transportation, material storage, logistics distribution, factory logistics turnover, etc.

As logistics developed in the 1970s, continuous improvements also made warehouse workers' jobs easier and order picking faster. The advent of mesh trolleys with wheels greatly simplified the movement of goods in warehouses. Roll Cage Trolleys are integral load carriers in many industries, from facilities such as hospitals, laundries, or supermarkets to retail chains transporting goods from warehouses or distribution centers to stores.

Robust and durable reel containers are true shipping masters: they are flexible, able to accommodate a wide variety of cargo, and transport products to their destinations safely and smoothly.

When choosing a Logistics Trolley, it is more important whether suitable for the existing supply chain. Perhaps your most common choice is the mesh cart, a continuation of the previous selection of the appropriate logistics tool. However, if not performing to its full potential, or finding the potential for improved transportation, consider selecting a more suitable design for your application.

Aceally roll cage trolleys use high-quality Q235 steel with galvanized surface treatment, ergonomic design, and easy maintenance, and are highly resistant to corrosion or other weathering conditions.

Roll Cage Trolley is our best-selling metal product and the workhorses of retail, supermarkets, and other industries. Our rolling containers are highly durable and reliable.

Our factory can customize and produce roll containers of various specifications according to business needs.

Interested in finding out more about Roll Container or Roll Cage Trolley Options for your warehouse? Request more information today.

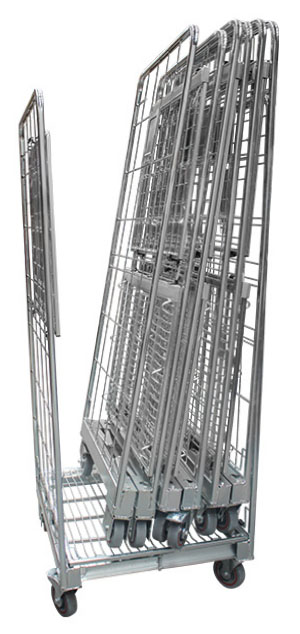

Folding Roll Container also called Collapsible Roll Container, or Folding Roll Cage, Collapsible Roll Cage, It refers to a container with a bottom (usually plastic) that can be folded lengthwise. Such a roll container saves a lot of space during transport and storage. It's an ideal solution for couriers, shipping lines, or companies that need extra rolling containers during periods of increased traffic. However, they don't want the rolling containers to take up too much space when they are not in use during the off-season. Then you may decide to choose a collapsible roll container.

The number of sides of a cart depends strictly on its use. It depends a lot on what it is supposed to be transporting and how well the product is to be protected. For example, to transport bulky items, 2-sided roll containers with only a base, wheels, and two fixed walls are often used. Straps can be used to secure cargo. However, for the collection of small items, 3-sided or 4-sided roll containers with metal shelves are usually ordered to separate the inner volume of the container, which not only increases the safety of workers but also protects the collected items in the lower part of the container comes from the weight of the stacked items.

Containers with more wire mesh on them mean you don't need to use as much stretch film as you used to, which has a positive effect on saving you money and protecting the environment by reducing the amount of unnecessary packaging.

Security roll containers, in turn, are so-called anti-theft products that are protected from theft because all sides of the container, including the upper surface, are closed with a net with a padlock or sealing lid. This allows for the safe transport of valuable products without the risk of damage or theft.

Our factory can customize and produce roll containers of various specifications according to business needs, interested in finding out more about Roll Container or Roll Container Options for your warehouse? Request more information today.

Storage Racks and Shelves are widely used in many modern enterprises, but many people only know how to use them but do not know how to protect and prolong their service life. Here, we will bring you some routine maintenance methods to help you prolong the service life of storage racks.

The cleaning and preservation aspects of the storage racks require our special attention. Here are 10 maintenance points:

Cleanliness is very important for a storage shelf because storage shelves are generally placed in the warehouse, and few people pay attention to the warehouse. Only when you need something will you think of it.

So few people clean the storage shelves. Frequent cleaning of storage shelves will prolong the service life of storage shelves. Cleaning storage shelves is not always done with water. Moreover, washing the shelf with water is easy to oxidize the surface of the shelf, which greatly shortens its service life of the shelf. Tools, accessories, and workpieces (products) shall be placed in order, and pipes and lines shall be in order to avoid blocking the channel. Moreover, the neatly placed storage shelves are not easy to hit, which increases the safety of storage shelves and goods.

Tools, accessories, and workpieces (products) shall be placed in order, and pipes and lines shall be in order to avoid blocking the channel. Moreover, the neatly placed storage shelves are not easy to hit, which increases the safety of storage shelves and goods.

Be sure to remember the weight of the storage shelf and don't put the goods outside the weight to avoid safety accidents.

The inherent parameters of storage shelves shall be strictly arranged to store goods. Being overweight will seriously affect the service life of storage shelves.

Properly ventilate the storage shelves, prevent wet goods from being placed on the storage shelves, and drain and dehumidify as much as possible.

The weight of goods placed on the storage shelf must be within the bearing capacity of the storage shelf. The warehouse keeper shall mark the bearing and ultimate load on the storage shelf.

According to different storage shelves, channel widths, and means of transport, a set of anti-collision columns shall be provided. Install crash barriers at access locations.

Different warehouses and different commodities have different convenient methods for the storage shelves of each warehouse. The ultimate way to achieve this goal is to establish a storage shelf use system for the warehouse keeper so that every storage shelf user can learn and abide by it.

Heavy and high-rise storage rack warehouses must be equipped with electric top trolleys, and the use and operation of top trolleys must be operated by licensed personnel. Most of the columns of warehouse shelves are deformed by non-designated personnel using carts.

Table of Contents

Maintain maximum selectivity and increase the efficiency of your operation with the ACL Pallet Shuttle. A Radio Shuttle, also known as a pallet runner, is a semi-automatic storage and retrieval system that maximizes warehouse space. The shuttle car can move along the track inside the storage aisle and is easily managed by remote control.

Warehouse operations run more smoothly because forklifts do not have to access racks, reducing the risk of accidents.

The forklift only leaves the load on the track, and the pallet shuttle automatically picks it up and moves it. The trays are as compact as possible, each slotted in its place. Since forklifts do not need to drive into the driveway, loading and unloading times are shorter, and storage capacity is higher and deeper.

In other words, the Pallet Shuttle System provides a compact storage solution that reduces operating costs and improves supply chain performance, enabling optimal smart warehousing.

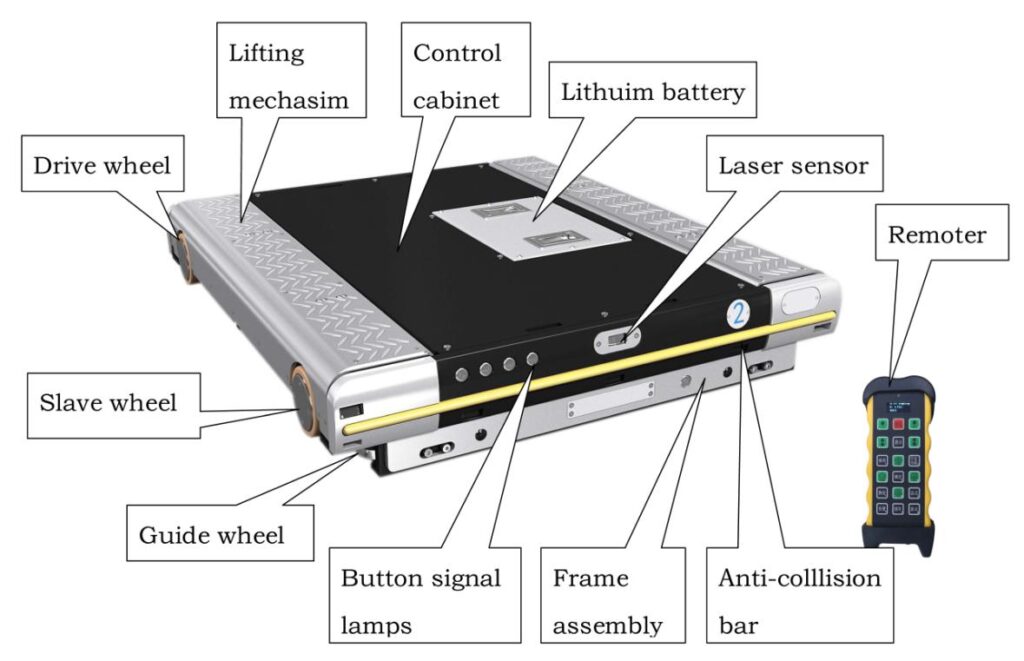

ACL Radio Shuttle consists of a base platform equipped with wheels to enable it to move, a pallet lifting system on the shuttle itself, and a long list of sensors and detection readers that collect information from its environment and enforce safety measures.

The shuttle is equipped with different status indicators to inform the operator of any possible error, battery level, or whether it is on or off.

Our Radio Shuttle comes in 8 styles: Economic Type, Standard Type, High-configuration type, Heavy loading type, and Low temp. type, Wifi type, Stacker type, M/S type. The following two tables are their technical parameters.

| Parameters | Economic type | Standard type | Advanced type | Heavy load type |

|---|---|---|---|---|

| Loading capacity max. | Max 1500kg | Max 1500kg | Max 1500kg | Max 2000kg |

| Running speed | Vmax_empty: 1.0m/s Vmax_full: 0.8m/s | Vmax_empty: 1.2m/s Vmax_full: 0.8m/s | Vmax_empty: 1.5m/s Vmax_full: 1.0m/s | Vmax_empty: 0.8m/s Vmax_full: 0.6m/s |

| Drive motor | Domestic brush /brushless servo motor 48VDC 600W | Imported brush servo motor 48VDC 600W | Imported brushless servo motor 48VDC 600W | Domestic brush motor 48VDC 800W |

| Servo driver | Domestic customized servo driver | Domestic customized servo driver | Imported brushless servo driver | Domestic customized servo driver |

| Lift motor | Domestic motor 48VDC 450W | Imported motor 48VDC 500W | Imported motor 48VDC 500W | Domestic motor 48VDC 540W |

| Lift height | ≤45mm | ≤45mm | ≤45mm | ≤45mm |

| Move positioning: Laser sensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Pallet positioning: Laser sensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Lift control: | proximity switch | Germany P+F | Germany P+F | Germany P+F/SICK |

| Object detection: photosensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Control system | Siemens S7-200 PLC | Siemens S7-200 PLC | Siemens S7-200 PLC | Siemens S7-200 PLC |

| Remoter: two-way | Customized IMT | Customized IMT | Customized IMT | Customized IMT |

| Power supply | Lithium battery | Lithium battery | Lithium battery | Lithium battery |

| Battery capacity | 48V, 30AH | 48V, 30AH | 48V, 30AH | 48V, 40AH |

| Running time | ≥8h | ≥8h | ≥8h | ≥8h |

| Charging time | 3~4H | 3~4H | 3~4H | 3~4H |

| Battery lifetime | Charge times≤1000 | Charge times≤1000 | Charge times≤1000 | Charge times≤1000 |

| Operation mode | Remote control | Remote control | Remote control | Remote control |

| Running noise | ≤60db | ≤60db | ≤60db | ≤60db |

| Painting color | Frame (black) Others (light gray) | Frame (black) Others (light gray) | Frame (red) Others (light gray) | Frame (black) Others (light gray) |

| Ambient temperature | Temp: 0℃~50℃ Humidity: 5%~95% | Temp: 0℃~50℃ Humidity: 5%~95% | Temp: 0℃~50℃ Humidity: 5%~95% | Temp: 0℃~50℃ Humidity: 5%~95% |

| Parameters | Low-temperature type | Wifi type | Stacker type | M/S type |

|---|---|---|---|---|

| Maximum payload | Max 1500kg | Max 1500kg | Max 1500kg | Max 1500kg |

| Running speed | Vmax_empty: 1.0m/s Vmax_full: 0.8m/s | Vmax_empty: 1.5m/s Vmax_full: 1.0m/s | Vmax_empty: 1.5m/s Vmax_full: 1.0m/s | Vmax_empty: 1.5m/s Vmax_full: 1.0m/s |

| Drive motor | Imported brush servo motor 48VDC 600W | Imported brushless servo motor 48VDC 600W | Imported brushless servo motor 48VDC 600W | Imported brushless servo motor 48VDC 600W |

| Servo driver | Domestic customized servo driver | Imported brushless servo driver | Imported brushless servo driver | Imported brushless servo driver |

| Lift motor | Imported motor 48VDC 500W | Imported motor 48VDC 500W | Imported motor 48VDC 500W | Imported motor 48VDC 500W |

| Lift height | ≤45mm | ≤45mm | ≤45mm | ≤45mm |

| Move positioning: Laser sensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Pallet positioning: Laser sensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Lift control: proximity switch | Germany P+F | Germany P+F | Germany P+F | Germany P+F |

| Object detection: photosensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Control system | Siemens S7-1200 PLC | Siemens S7-1200 PLC | Siemens S7-1200 PLC | Siemens S7-1200 PLC |

| remoter: two way | Customized IMT | Customized IMT | Spare domestic | Spare domestic |

| Power supply | Lithium battery | Lithium battery | Lithium battery | Lithium battery |

| Battery parameter | 48V, 40AH | 48V, 30AH | 48V, 30AH | 48V, 30AH |

| Run time | ≥8h | ≥8h | ≥8H | ≥8H |

| Charging time | 3~4H | 3~4H | 3~4H | 3~4H |

| Battery lifetime | Charge times≤1000 | Charge times≤1000 | Charge times≤1000 | Charge times≤1000 |

| Operation mode | Remote control | WCS dispatch/ Remote control | WCS dispatch/ Remote control | WCS dispatch/ Remote control |

| Running noise | ≤60db | ≤60db | ≤60db | ≤60db |

| Painting | Frame (black) Others (light gray) | Frame (red) Others (light gray) | Frame (red) Others (light gray) | Frame (black) Others (light gray) |

| Ambient temperature | Temp: -25℃~50℃ Humidity: 5%~95% | Temp: 0℃~50℃ Humidity: 5%~95% | Temp: -25℃~50℃ Humidity: 5%~95% | Temp: 0℃~50℃ Humidity: 5%~95% |

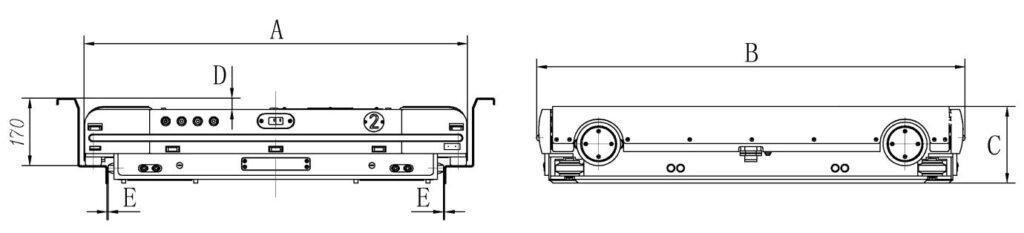

| Model | Pallet sizes (mm) | Weight (kg) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) |

|---|---|---|---|---|---|---|---|

| ACLII-1012 | 1000X1200 | 285 | 831 | 1270 | 193 | 27 | 3 |

| ACLII-1113 | 1100X1300 | 295 | 873 | 1370 | 193 | 27 | 3 |

| ACLII-1210 | 1200X1000 | 280 | 957 | 1070 | 193 | 27 | 3 |

| ACLII-1211 | 1200X1100 | 290 | 957 | 1170 | 193 | 27 | 3 |

| ACLII-1212 | 1200X1200 | 300 | 957 | 1270 | 193 | 27 | 3 |

| ACLII-1213 | 1200X1300 | 310 | 957 | 1370 | 193 | 27 | 3 |

| ACLII-1214 | 1200X1400 | 320 | 957 | 1470 | 193 | 27 | 3 |

| ACLII-1215 | 1200X1500 | 335 | 957 | 1570 | 193 | 27 | 3 |

| ACLII-1216 | 1200X1600 | 345 | 957 | 1670 | 193 | 27 | 3 |

| ACLII-1311 | 1300X1100 | 300 | 1057 | 1170 | 193 | 27 | 3 |

| ACLII-1410 | 1400X1000 | 310 | 1157 | 1070 | 193 | 27 | 3 |

| ACLII-1411 | 1400X1100 | 320 | 1157 | 1170 | 193 | 27 | 3 |

| ACLII-1412 | 1400X1200 | 330 | 1157 | 1270 | 193 | 27 | 3 |

| ACLII-1414 | 1400X1400 | 355 | 1157 | 1470 | 193 | 27 | 3 |

| ACLII-1415 | 1400X1500 | 365 | 1157 | 1570 | 193 | 27 | 3 |

Note:

Different dimensions of radio shuttle can be tailor-made as per various kinds of pallets and rails.

Pallet sizes, i.e. 1200X1000 (front number 1200 means fork-in direction /width direction, rear number 1000 means width direction)

The rescue vehicle of the radio shuttle is equipment to drag the radio shuttle to the cargo rack port, when the radio shuttle cannot move on the rack due to trouble. Manual mode is adopted to make forward or backward with the handle.

The operating method is as follows:

First of all, the rescue vehicle is forked to the radio shuttle rail by forklift, then the operator moves the rescue vehicle to the faulty radio shuttle. Firstly switch off the main power supply of the radio shuttle, then connect the radio shuttle to the rescue vehicle by the hook. Then move them to the cargo rack port by the manual handle. Remove the hook, then fork out the rescue vehicle and radio shuttle separately.

The charging cabinet, equipment to charge the battery of the radio shuttle, has two charging positions. The charging position circuit is designed with an independent power supply, which can charge two batteries simultaneously or charge one battery together. Charging will automatically stop when the battery is fully charged. The charging cabinet has simple operation and convenient application.

When working on higher racks, forklift operators often drop off radio shuttles due to insufficient sight or less experience. In order to solve this problem, our company has developed a set of auxiliary placement systems for the radio shuttle, which can provide the forklift with a visual interface to prevent the radio shuttle from dropping off by misoperation.

When a radio shuttle is rescued by a rescue vehicle, the radio shuttle with cargo is hardly dragged out if the radio shuttle is on heavy duty. By means of this auxiliary system, pallets can be firstly placed on the rail, then radio shuttle directly dragged out!

Push Back Pallet Racking is a gravity flow racking system for the accumulation of pallets, designed for FILO load management (first pallet in, last pallet out).

Push-back pallet rack provides high-density storage where pallets are stored up to five deep. Using a forklift, pallets are pushed back on inclined rails mounted inside the racking. When a pallet is withdrawn, the one behind automatically slides forward to the front position of the pallet racking.

Push back rack is a live storage system that stores pallets on wheeled carts nesting on inclined storage rails. When a product is loaded into a push-back racking system, a pallet is placed onto a cart and pushes the pallet at the pick face back in one position.

Push-back racking for pallets has a single loading and unloading area, at the front of the structure, and the unit loads are stored by pushing the previous ones toward the back of the rack.

It can also be combined with other storage systems which makes it a versatile solution.

Push-back racking has enjoyed rapid growth in popularity recently due to offering similar space savings as a drive-in, with typically 3 to 5 times greater selectivity. This growth has been spurred by marketing trends such as rapid increases in the number of SKUs, mass customization, and more rapid product obsolescence.

Each level in a push-back system holds a series of nested rolling carts, operating in a lane that slopes upward away from the pick face.

Improved selectivity over Drive-In, which Push-Back often replaces.

Efficiency vs. Drive-In – trucks do not need to drive into rack loads that come to them at the pick face.

Less rack. Truck and product damage vs. Drive-In- with no trucks driving inside the rack.

There are a number of particular factors to satisfy before making a push-back purchase:

Interested in finding out more about Push Back Pallet Racking or Push Back Pallet Racking options for your warehouse? Request more information now.

Very Narrow Aisle Pallet Racking (VNA) combines the advantages of adjustable pallet racking and compact pallet racking systems with better use of the available space while maintaining direct access to all the stored unit loads.

Aceally VNA pallet racking systems are designed to meet the new generation of warehouses up to 17 meters high, designed around the operating tolerances of Very Narrow Aisle (VNA) equipment with aisles marginally wider than the load. Such structures must have a high level of rigidity and accurate manufacturing tolerance.

Increased capacity with increased height

Warehouse capacity can be increased by an additional 40% over Selective Pallet Racking by increasing operational height and reducing operation aisle.

VNA Very narrow aisle rack is a widely used solution as it is very versatile and optimizes space.

Especially recommended for companies whose warehouses have any of the following characteristics:

Designed to meet the new generation of distribution centers up to 17 meters high, it requires a super flat floor.

Interested in finding out more about narrow aisle racking or very narrow aisle racking options for your warehouse? Request more information now.

A Beam Connector is also known as a Beam Hook. It is a kind of racking accessory. We offer a variety of beam hooks to clients all over the world.

Custom sizes and colors are also available.

Custom designed and built to meet your specific needs and requirements.

Supply Ability: 50000 Tons per Month.

We offer professional consultation and design. Allow our experienced engineers to assist you in designing a storage system that best suits your particular needs.

We also FREE offer:

Interested in finding out more about Pallet Racking Beam Connectors or Other Racking Accessories for your warehouse? Request more information now.